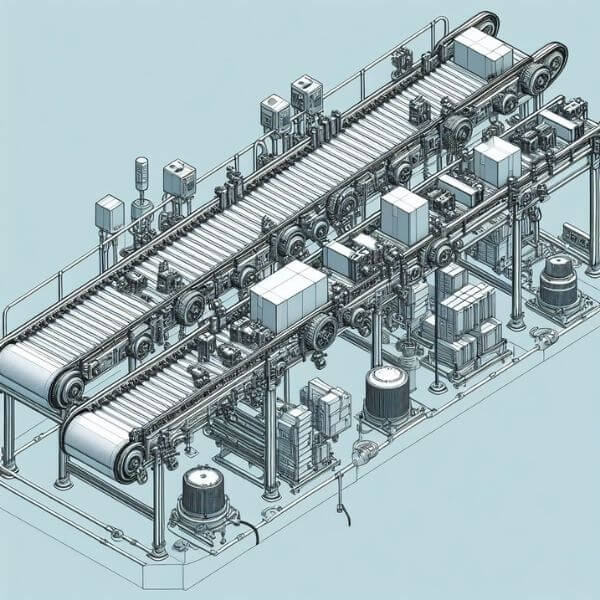

Parallel Load Transfer Systems

Our Parallel Load Transfer System stands out from other solutions on the market. It is designed to respond to the diversifying and growing needs of our customers. These systems offer the capacity to transport materials at high speed and without interruption. At the same time, the flexible nature of these systems ensures that they are perfectly adaptable to different industrial scenarios and applications. Thus, we create an effective solution to customers’ customized needs.

What are Parallel Load Transfer Systems and Why Are They Important?

Parallel load transfer systems are a type of conveying system used to optimize material handling and placement processes in industrial plants. These systems have a unique design that allows multiple loads to be transported simultaneously and in parallel. For use, they are usually integrated with conveyor systems, robotic arms or other automated handling mechanisms.

They play a critical role in increasing the production efficiency of the industrial plant, optimizing handling operations and speeding up business processes. Thus, parallel load transfer systems allow multiple loads to be transported simultaneously, saving time and energy. With the right integration, they minimize errors and strengthen operational excellence.

What are the Advantages?

1. High Speed and Efficiency: It has the capacity to carry more than one load at the same time. Thus, it provides high efficiency by accelerating production processes.

2. Flexible Application Areas: They can be flexibly adapted to various industrial application areas. These systems can be used in different sectors and for various transportation needs.

3. High Accuracy and Sensitivity: Thanks to integrated sensors and control systems, it operates with high accuracy and precision. This ensures reliability in product placement and handling.

4. Human Security: Thanks to their automatic operating principles, parallel load transfer systems increase human safety in the workplace. Operators can move away from dangerous environments and a safer working environment is created.

5. Low Operating Costs: Thanks to their automatic operation and high efficiency, they reduce operating costs. This provides long-term cost advantages through reduced energy consumption and low maintenance requirements.

6. Production Continuity: Automated and parallel handling features ensure that production processes run in a more controlled and continuous manner. This increases production continuity and minimizes unexpected downtime.

7. Ease of Integration: Parallel load transfer systems can often be easily integrated with other automation systems and industry 4.0 solutions. This allows industrial plants to create a more intelligent and integrated production process.

8. Sustainability: Efficient and optimized work processes lead to energy savings and a reduction in material use. This enables parallel load transfer systems to contribute to sustainability goals.

Our Parallel Load Transfer Systems are world-class technology that offers solutions to the complex transportation needs of industrial plants. High speed, flexible application areas, low operating costs and sustainability are our principles. In this way, we offer our customers future-proof, intelligent and efficient transportation solutions. Working with Prode Roller allows industrial plants to take a step towards increasing their competitive advantage and optimizing their production processes.