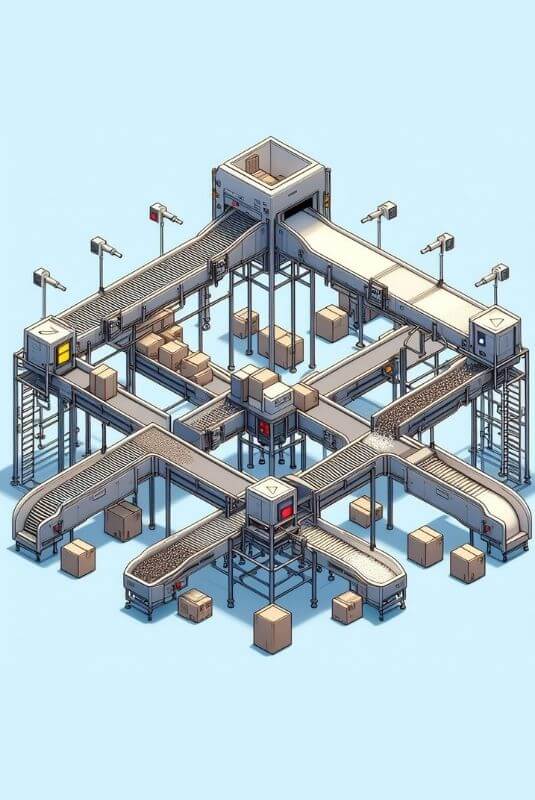

Four Way Separation Conveyor/Sorter

Prode Roller maintains its leading position in industrial conveying and sorting systems, offering customers a solution that provides high productivity and flexibility. The Four-Way Sorting Conveyor/Sorter allows businesses to optimize their production processes. It also enables fast and precise sorting of products. Our expertise and innovative approach exceed industry standards. This allows us to increase customer satisfaction and provide a solution that is constantly evolving.

What is a Four-Way Separation Conveyor/Sorter and Why is it Important?

The Four-Way Sorting Conveyor/Sorter is a special conveyor system that can direct materials in four different directions in industrial plants. This system is especially used to optimize sorting operations in sectors such as logistics, e-commerce and manufacturing. The products are arranged in a specific order on the conveyor and directed to four different exit points.

It allows industrial facilities to perform sorting operations in a faster, organized and effective way. Especially for businesses with a variety of products, this system provides a competitive advantage by increasing operational efficiency. It also plays an important role in logistics processes by enabling fast and accurate deliveries.

What are the Advantages?

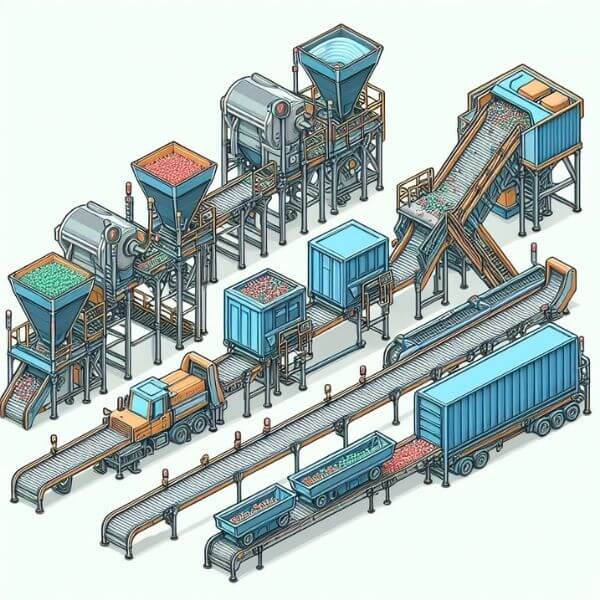

1. Fast and Accurate Sorting: Identifies products quickly. It directs them in four different directions according to the determined order. This ensures that sorting operations are carried out quickly and accurately.

2. Flexible Configuration: These conveyor systems offer flexible configuration options for sorting various product types and sizes. This feature is ideal for adapting to different industrial needs.

3. Operational Efficiency: The Four-Way Sorting Conveyor/Sorter increases the operational efficiency of businesses. Faster sorting and routing optimizes work processes.

4. Precise and Reliable Sensors: Thanks to integrated sensors, conveyor systems detect products precisely. This creates a reliable basis for correct sorting and routing.

5. Low Manpower Requirement: Automatic and robot-assisted working principles ensure that the Four-Way Separation Conveyor/Sorter has low manpower requirements. Thus, the labor costs of the enterprises are reduced.

6. Flexible Exit Points: The Four-Way Separation Conveyor/Sorter can route products to four different exit points. This flexibility means better planning and management of storage and logistics processes.

7. Various Application Areas: These conveyor systems offer a wide range of applications in various industry sectors such as logistics, e-commerce, manufacturing and warehousing.

8. High Capacity and Durability: The Four Way Separation Conveyor/Sorter usually has a high capacity and is manufactured from durable materials. These features increase suitability for intensive and continuous use.

Prode Roller’s Four-Way Sorting Conveyor/Sorter service offers a smart and efficient solution to the sorting needs of industrial plants. Fast, accurate and flexible sorting processes enable businesses to gain a competitive advantage by increasing their operational efficiency. Working with Prode Roller means a more efficient and optimized logistics and handling process.